H frame Hydraulic Press Machine Deep Drawing 1720T

Basic Info

Model No.: Yz27

Product Description

Hydraulic Deep Drawing Press Metal Stamping Press

Compared with the traditional stamping process, the hydroforming process has obvious technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, increasing rigidity and strength, and reducing production costs. It has been obtained in the industrial field, especially in the automotive industry. More and more applications. Powder Compression Press

Frame-type hydraulic machine three-beam four-column structure, economical and practical, hydraulic control adopts cartridge valve integrated system, reduce leakage point, reliable action, long service life, can realize two forming processes of constant pressure and fixed stroke, with pressure-holding delay function, work The pressure stroke can be adjusted within the specified range. The centralized control of the button can realize three operation modes: manual, semi-automatic and automatic. YW96K large cab frame hydraulic machine adopts two-way cartridge valve; electrical control system can be equipped with "PLC" programmable controller, and has independent electrical and hydraulic power mechanism. Adjustable, manual and semi-automatic operation modes are realized by centralized control of buttons. This machine is suitable for stretching, bending, flanging, correction, press-fit and cold and hot extrusion. According to the needs of users, it can be equipped with functions such as digital display and pressure digital display.

The hydraulic system's drive system mainly has two types: pump direct drive and pump-accumulator drive. Others C type Hydraulic Press

The pump of the drive system system supplies high pressure working fluid to the hydraulic cylinder, the flow regulating valve is used to change the direction of the liquid supply, and the relief valve is used to adjust the defined pressure of the system and at the same time function as a safe overflow. The drive system has few links and simple structure, and the pressure can be automatically increased or decreased according to the required working force, thereby reducing the power consumption, but the maximum working force and the maximum working speed of the hydraulic machine are required to determine the capacity of the pump and its driving motor. This type of drive system is mostly used for small and medium-sized hydraulic presses, as well as large (such as 120,000 kN) free forging hydraulic presses that are directly driven by pumps. Forging Hydraulic Press

Precautions for frame hydraulic presses during city test:

Before starting the machine, you must understand the mechanical principle of the machine, let the motor run 2-3 times. If the inverter is reversed, adjust the two-phase power cord. After replacing the hydraulic oil, the pressure of the relief valve should be adjusted to a small value. After normal operation, slightly increase the pressure, drain the air in the system and test the pressure.

Features

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

Parameters

| Mold | unit | 63T | 100T | 160T | 200T | 250T | 315T | 500T | 630T | 800T | 1000T | 1250T | |

| Main cylinder (slider) process specs | Max.press force | KN | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 30000 |

| Max.return force | KN | 150 | 100 | 315 | 450 | 540 | 630 | 1000 | 1000 | 1200 | 1600 | 2100 | |

| Down speed | mm/s | 100 | 100 | 160 | 160 | 140 | 140 | 140 | 250 | 200 | 150 | 150 | |

| Slow speed | mm/s | 20 | 15 | 15 | 15 | 12 | 15 | 15 | 15 | 15 | 15 | 12 | |

| The proportion of floating pressing speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Press speed | mm/s | 10 | 10 | 10 | 10 | 7 | 8 | 8 | 8 | 8 | 8 | 6 | |

| Return speed | mm/s | 120 | 120 | 120 | 110 | 95 | 100 | 100 | 150 | 150 | 120 | 120 | |

| Max.stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | |

| Top cylinder process specs | Max.ejection force | KN | 280 | 440 | 450 | 900 | 900 | 1250 | 1800 | 2200 | 2200 | 2750 | 10000 |

| Max.pull force | KN | 280 | 360 | 450 | 750 | 750 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Eject speed | mm/s | 80 | 34 | 65 | 55 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Floating speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Return speed | mm/s | 80 | 42 | 95 | 70 | 70 | 50 | 50 | 60 | 60 | 60 | 60 | |

| Upper center cylinder process specs | Max.press force | KN | 60 | 60 | 60 | 125 | 150 | 125 | 200 | 200 | 240 | 240 | 500 |

| Max.return force | KN | 30 | 30 | 30 | 76 | 76 | 76 | 130 | 130 | 140 | 140 | 200 | |

| Max.stroke | mm | 30 | 30 | 30 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 | |

| Under center cylinder process specs | Max.press force | KN | 70 | 70 | 125 | 160 | 160 | 200 | 200 | 300 | 300 | 300 | 1000 |

| Max.return force | KN | 40 | 40 | 75 | 100 | 100 | 100 | 100 | 200 | 200 | 200 | 260 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Upper floating cylinder process | Max.press force | KN | 120 | 120 | 130 | 250 | 250 | 300 | 400 | 400 | 480 | 480 | 1000 |

| Max.return force | KN | 60 | 60 | 65 | 150 | 150 | 160 | 200 | 200 | 240 | 240 | 250 | |

| Max.stroke | mm | 45 | 45 | 50 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 70 | |

| Effective worktable size | L-R | mm | 580 | 720 | 780 | 1000 | 1000 | 1000 | 1200 | 1320 | 1400 | 1600 | 2400 |

| F-B | mm | 490 | 580 | 640 | 940 | 940 | 960 | 1140 | 1200 | 1200 | 1350 | 1460 | |

| Max.pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max.filling height | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | |

| Main motor power | KW | 7.5 | 11.5 | 18.5 | 22 | 22 | 30 | 48 | 67 | 82 | 100 | 100 | |

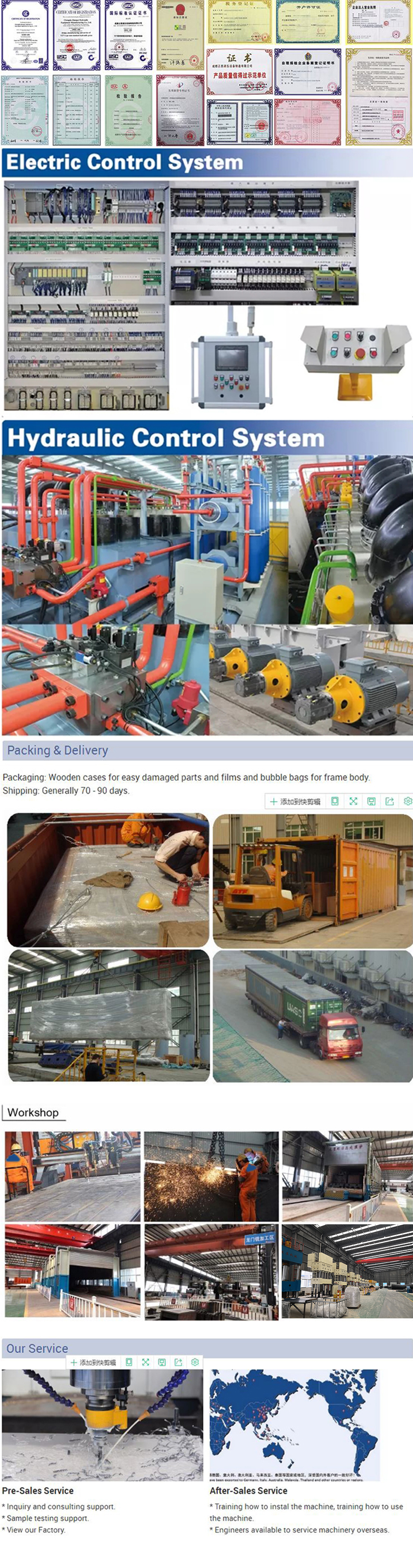

Certificate

Packaging and delivery

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Chengdu City ,Sichuan Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : H Type Hydraulic Press > Single Action Sheet Deep Drawing