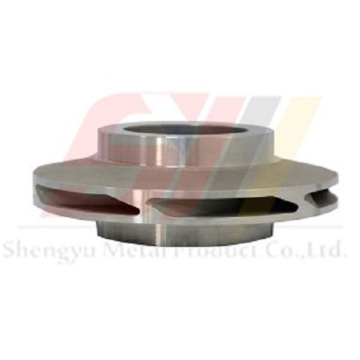

Customized Parts Water Pump Impeller

Product Description

Disadvantages of Investment Casting

1. Compared to other Metal Casting methods, investment casting involves many complicated steps, making the process relatively expensive. But for some products, certain steps can be automated. It may be more expensive than Die Casting or Sand Casting, but the unit cost will decrease as production increases.

2. High-cost molds to make models have traditionally limited investment casting

3. The high cost is also due to specialized equipment requirements, expensive refractories and high labor costs

4. Parts requiring cores are difficult to cast, have holes smaller than 1.6 mm or depths greater than 1.5 times the diameter

Over the centuries, various combinations of raw materials have been developed to produce various metal types. Some cast products are used in engines that require high heat and cold resistance. Cast Iron Pipes must be resistant to corrosion and high pressure. Other castings must be lightweight but durable. In many applications, parts are designed to allow precise tolerances between expansion and contraction.

Other casting processes include gypsum casting, die casting and investment casting. Gypsum casting simply replaces sand with a plaster mold.

Cast Iron Water Pump Parts Vacuum Pump Spare Parts Hand Water Pump Parts Hand Pump Spare P

Die casting requires two large moving non-ferrous metal parts that are clamped together under high pressure. The molten metal is injected into the mold, and the metal parts are separated after hardening.

The process of investment casting begins by filling the mold with wax. Once the wax hardens, it coats the ceramic material several times. Heat until the wax melts and retains the ceramic mold. The mold is filled with molten metal, cooled, and the ceramic material is broken off.

Metal casting is a modern craft with ancient roots. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, cooling it in the mold cavity, and then removing it from the mold. Metal casting can be said to be the earliest and most influential industrial process in history. It has been used to make many metal objects that we use in our daily lives: car parts, train wheels, lamp posts, school bus pedals, and more. Additionally, metal foundries rely on metal recycling as a cost-effective source of raw materials, thereby significantly reducing scrap metal that may end up in landfills.

Cast Iron Water Pump Parts Vacuum Pump Spare Parts Hand Water Pump Parts Hand Pump Spare Parts

Product Categories : Impeller Accessories

Hot Products

Cold chamber ADC-12 die cast housing for solar street light0001371006 Truck StarterServo Motor Application,Cast Aluminum Spare Partsdie cast handleCommunication Equipment Die Casting Telecommunication PartsStamping Parts Furniture Hardware Funiture BracesStamping Parts Stamping Outdoor Camera ShieldDie Casting LED Lamp Front CoversCCTV Security Camera Dome Case PartsStamping Sheet Metal Fabrication Case PartsCustom Made Die Casting Car Spare PartsLow Cost High Quality aluminum led heatsink profile priceProfessional Customized Parts /CNC Precision Machining Parts2016 hot sale high precision aluminum stamping partsAluminium Die Casting Custom Motor Casing PartsBest Selling Products Aluminum Die Casting