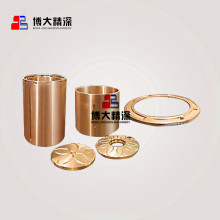

Precision Lost Wax Casting Silicon Bronze Casting

Basic Info

Model No.: bronze casting

Product Description

Model NO.: bronze casting Casting Form Material: Bronze Casting Form Usage Count: Permanent Machining Tolerance: +/-0.01mm Weight: 0.2 to 50 Kgs Type: Brass Brozen Copper Trademark: Mingda Origin: Hebei, China Casting Method: Investment Casting Casting Metal: Bronze Surface Treatment: Polishing Certification: SGS, ISO 9001:2008 Size: as Per Drawing Machining: CNC Machining Specification: SGS HS Code: 7401000010

Precision Lost Wax Casting silicon bronze casting

Product description

Detailed Quality Control In Manufacturing Process

Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each

material purchasing lot.

Equipment Maintain

Machining equipments maintain: Checked by each day, have records to track.

Inspection equipment maintain: Checked by each 15 days, have records to track.

Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to

track.

Packing and Assembly

To meet custom requirments, including labels, cartons, pallets etc before shipment. Contact us if you need more details on Machining parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting、Brass Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Precision Lost Wax Casting silicon bronze casting

Product description

| Material | Brass or Copper Alloy Non ferrous alloys Bronze Copper Casting . Brass is 319 type or BS 249 type . Any special Brass Material Composition as per Customers Requirement . Brass to BS 2874 / 2872. Brass natural, Electro-Tinned, Nickel etc. |

| Weights | from 10 Grams to 40 kg's. |

| Size | Specification or as per Custom Design or Requirement.. |

| Finish And Coating | Natural, Nickel Plated, Tin Plated Or Any Coating As Per Customer Specification. Any Kind Of Special Die Casting Sand Gravity Die Lost Wax Shell Molding Castings And Cast Parts Casting Produced To User Specifications. |

Detailed Quality Control In Manufacturing Process

Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each

material purchasing lot.

Equipment Maintain

Machining equipments maintain: Checked by each day, have records to track.

Inspection equipment maintain: Checked by each 15 days, have records to track.

Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to

track.

Packing and Assembly

To meet custom requirments, including labels, cartons, pallets etc before shipment. Contact us if you need more details on Machining parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting、Brass Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Bronze and Brass Casting

Premium Related Products

Other Products

Hot Products

Cold chamber ADC-12 die cast housing for solar street light0001371006 Truck StarterServo Motor Application,Cast Aluminum Spare Partsdie cast handleCommunication Equipment Die Casting Telecommunication PartsStamping Parts Furniture Hardware Funiture BracesStamping Parts Stamping Outdoor Camera ShieldDie Casting LED Lamp Front CoversCCTV Security Camera Dome Case PartsStamping Sheet Metal Fabrication Case PartsCustom Made Die Casting Car Spare PartsLow Cost High Quality aluminum led heatsink profile priceProfessional Customized Parts /CNC Precision Machining Parts2016 hot sale high precision aluminum stamping partsAluminium Die Casting Custom Motor Casing PartsBest Selling Products Aluminum Die Casting