Aluminum Die Casting (EN AC-43400/AlSi10Mg, A360.0)

Basic Info

Model No.: A360.0, EN AC-43400/AlSi10Mg

Product Description

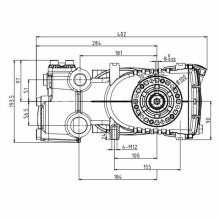

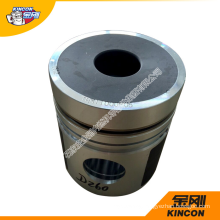

Model NO.: A360.0, EN AC-43400/AlSi10Mg Surface Preparation: Polishing Trademark: MINGDA Origin: Hebei China Material: Aluminum Application: Industry of Automobile, Gearbox Transmission, Moto Specification: SGS 1. Application: Our Die Casting Products are widely used in the industry of automobile, gearbox transmission, Motorcycle, electronic, etc.

2. Quality: Each step in the process requires inspections with special gauges, measurement tools and testing equipment. Our inspection teams ensure that tolerances conform to your exact specifications and that overall quality is maintained.

We assure dimension and material composition 100% meets customer's standards.

Our craftsmen have over 15 years average tenure, so you know you are dealing with people who know the system

3. Die Casting process

Die casting is a Metal Casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Die-casting can be done using a cold chamber or hot chamber process.

In a cold chamber process, the molten metal is ladled into the cold chamber for each shot. There is less time exposure of the melt to the plunger walls or the plunger. This is particularly useful for metals such as Aluminum, and Copper (and its alloys) that alloy easily with Iron at the higher temperatures.

In a hot chamber process the pressure chamber is connected to the die cavity is immersed permanently in the molten metal. The inlet port of the pressurizing cylinder is uncovered as the plunger moves to the open (unpressurized) position. This allows a new charge of molten metal to fill the cavity and thus can fill the cavity faster than the cold chamber process. The hot chamber process is used for metals of low melting point and high fluidity such as tin, zinc, and lead that tend not to alloy easily with steel at their melt temperatures.

Die casting molds (called dies in the industry) tend to be expensive as they are made from hardened steel-also the cycle time for building these tend to be long. Also the stronger and harder metals such as iron and steel cannot be die-cast. Contact us if you need more details on Aluminum Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum casting、Pressure Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

2. Quality: Each step in the process requires inspections with special gauges, measurement tools and testing equipment. Our inspection teams ensure that tolerances conform to your exact specifications and that overall quality is maintained.

We assure dimension and material composition 100% meets customer's standards.

Our craftsmen have over 15 years average tenure, so you know you are dealing with people who know the system

3. Die Casting process

Die casting is a Metal Casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Die-casting can be done using a cold chamber or hot chamber process.

In a cold chamber process, the molten metal is ladled into the cold chamber for each shot. There is less time exposure of the melt to the plunger walls or the plunger. This is particularly useful for metals such as Aluminum, and Copper (and its alloys) that alloy easily with Iron at the higher temperatures.

In a hot chamber process the pressure chamber is connected to the die cavity is immersed permanently in the molten metal. The inlet port of the pressurizing cylinder is uncovered as the plunger moves to the open (unpressurized) position. This allows a new charge of molten metal to fill the cavity and thus can fill the cavity faster than the cold chamber process. The hot chamber process is used for metals of low melting point and high fluidity such as tin, zinc, and lead that tend not to alloy easily with steel at their melt temperatures.

Die casting molds (called dies in the industry) tend to be expensive as they are made from hardened steel-also the cycle time for building these tend to be long. Also the stronger and harder metals such as iron and steel cannot be die-cast. Contact us if you need more details on Aluminum Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum casting、Pressure Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Aluminum casting > Aluminum die casting parts

Premium Related Products

Other Products

Hot Products

Cold chamber ADC-12 die cast housing for solar street light0001371006 Truck StarterServo Motor Application,Cast Aluminum Spare Partsdie cast handleCommunication Equipment Die Casting Telecommunication PartsStamping Parts Furniture Hardware Funiture BracesStamping Parts Stamping Outdoor Camera ShieldDie Casting LED Lamp Front CoversCCTV Security Camera Dome Case PartsStamping Sheet Metal Fabrication Case PartsCustom Made Die Casting Car Spare PartsLow Cost High Quality aluminum led heatsink profile priceProfessional Customized Parts /CNC Precision Machining Parts2016 hot sale high precision aluminum stamping partsAluminium Die Casting Custom Motor Casing PartsBest Selling Products Aluminum Die Casting